Introduction to Relays

A relay is an electronic device widely used in various electrical and electronic systems. It is an electromagnetic switch that can control the state of another circuit in one circuit while isolating the two circuits. Relays play a crucial role in automation, control systems, automotive electrical systems, and more. They come in different types and serve various purposes.

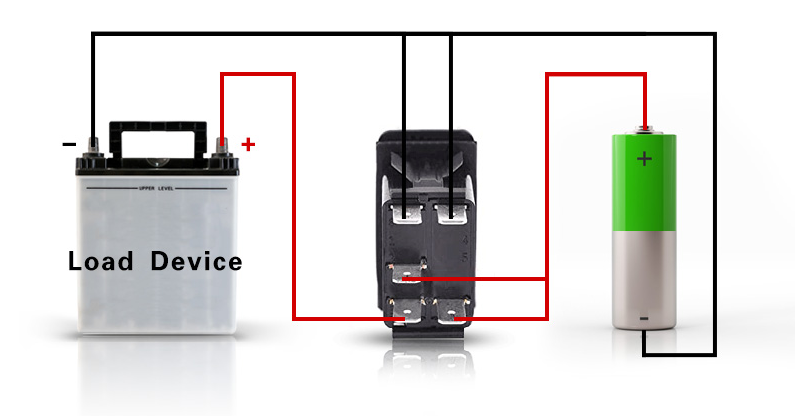

The working principle of a relay is simple; it uses an electromagnetic coil to control one or more switches. When current passes through the coil, it generates a magnetic field that attracts or pushes one or more mechanical switches, thereby changing their state. This process can be used to control the flow of current and achieve various circuit functions.

Types of Relays

There are many types of relays, depending on their use and characteristics, including automotive relays, electrical relays, timer relays, temperature relays, and more. Let’s explore some common types of relays and their applications.

Automotive Relay: Automotive relays are specifically designed for use in automotive electrical systems. They are used to control various functions in vehicles, such as headlights, air conditioning, power windows, and more. Common types include turn signal relays and fan relays.

Electrical Relay: Electrical relays find applications in industrial and household electrical systems, where they control motors, lighting, heaters, and other devices. They can switch circuits in different ways to meet specific application requirements.

Timer Relay: Timer relays are used to control operations that occur at specific time intervals, such as timing lights or starting equipment at predetermined times.

LED Flasher Relay: LED flasher relays are designed to control the LED lights in vehicles to ensure they flash at the correct rate and pattern, such as turn signals.

4 Pin Relay and 5 Prong Relay: These relays are often used in simple switching applications, including normally open (NO) and normally closed (NC) contacts. They have widespread use in circuits for basic control functions.

Relays are used in various industries and fields:

Absolutely, relays are indispensable components in numerous industries and fields. They serve as electrically operated switches, allowing low-power signals to control higher-power circuits. Industries such as manufacturing, automotive, telecommunications, aerospace, and power generation rely on relays for tasks ranging from controlling machinery to managing power distribution. Their versatility and reliability make them essential across a wide spectrum of applications.

Industrial Automation: Relays are essential for controlling devices like robotic arms, conveyor belts, and machinery in industrial automation.

Power Systems: In power systems, relays are used to protect electrical equipment, monitor grid conditions, and manage power loads.

Automotive Manufacturing: Relays control various electrical systems in vehicles, including engine management, lighting, and safety systems.

Home Automation: In home automation, relays are used to control lighting, HVAC systems, and household appliances. They enable remote operation and automation scenarios.

Aerospace: In the aerospace industry, relays are used to control various systems on aircraft, including communication, navigation, and power systems.

In automation systems, relays serve several critical functions:

Logic Control: Relays are used for logic control, triggering different output actions based on various input conditions. This logic control is central to automation systems.

Timing Tasks: Timer relays ensure precise timing of operations, such as scheduled equipment activation or deactivation, crucial in automated production lines.

State Monitoring: Relays are used to monitor the status of equipment and systems. When a change in state occurs, relays can trigger actions like alarms or shutdowns.

Remote Control: Integrated into automation systems, relays enable remote control, allowing operators to manipulate devices and systems from a distance.

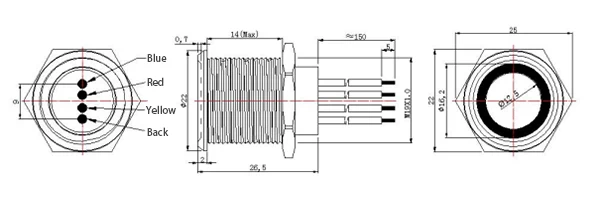

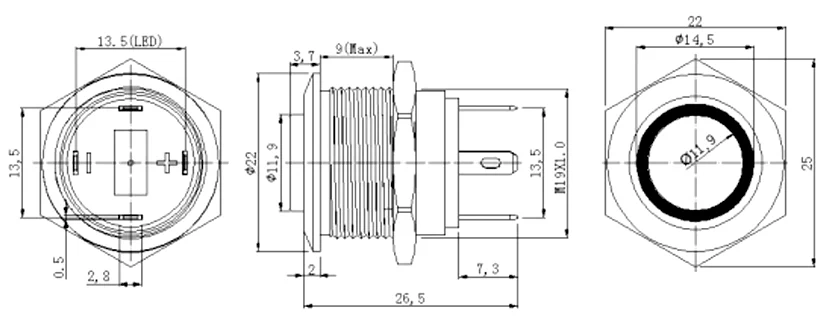

Relays are often accompanied by complementary components like indicator lights, push button switch, and toggle switches. Indicator lights display the relay’s operating status, while push-button switches and toggle switches can be used for manual control in automation systems.

In summary, relays are indispensable components in electrical and electronic control systems, serving various functions and finding applications in numerous industries. Different types of relays cater to specific needs, from automotive manufacturing to industrial automation and home automation. They provide logic control, timing tasks, state monitoring, and remote control capabilities, all while working in tandem with components like indicator lights and switches to create efficient electrical control systems. As technology continues to advance, relays will continue to play a crucial role in automation and electrical engineering, bringing convenience and efficiency to our lives and work.