Terminal blocks serve as pivotal components in electrical systems, revolutionizing connectivity and streamlining wiring processes across various industries. From industrial automation to building wiring, these versatile blocks have become indispensable. Understanding their types, components, installation processes, and maintenance is crucial for optimal utilization.

Terminal blocks, also known as connection terminals or terminal connectors, are fundamental components in electrical circuits. They serve as junction points for electrical wires, providing a secure and organized method for connecting different electrical components.

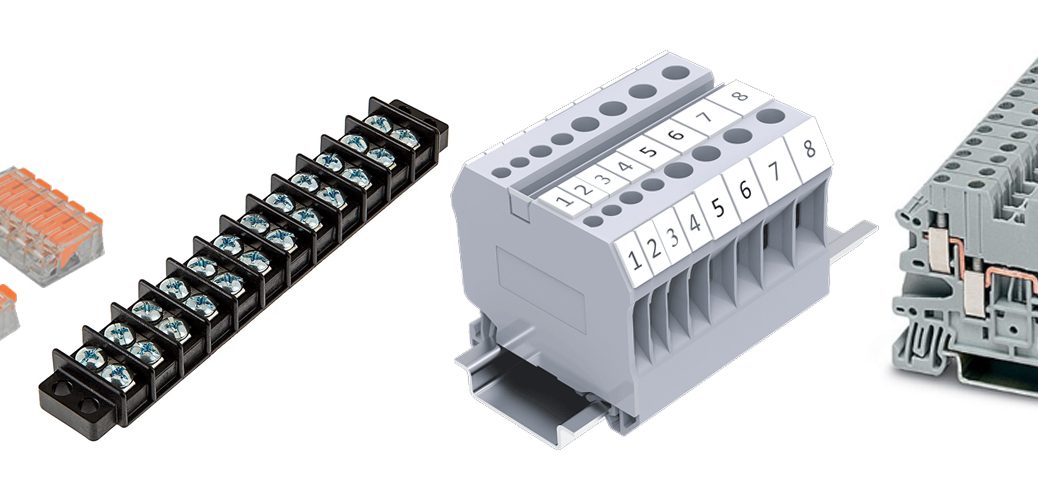

Types of Terminal Blocks

There are several types of terminal blocks tailored to specific applications. Barrier terminal blocks offer insulation and segregation between circuits, while DIN rail terminal blocks are commonly used in industrial settings for their easy installation on DIN rails. PCB terminal blocks are designed for printed circuit boards, and plug-in terminal blocks allow quick connections and disconnections.

Components and Structure

Terminal blocks typically consist of screw terminals or spring terminals, where wires are inserted and secured. The choice between these terminals often depends on the application and required ease of wiring. The structure includes insulation materials to prevent short circuits and various wiring options to accommodate different wire gauges and types.

Installation and Wiring Process

Installing terminal blocks involves a step-by-step process, from choosing the right block for the application to wiring techniques. Ensuring proper insulation, wire stripping, and secure connections is vital for efficient functionality and safety.

Advantages of Terminal Blocks

The versatility and flexibility of terminal blocks allow for easy modifications and additions to electrical systems. They facilitate straightforward maintenance and troubleshooting due to their organized structure. Safety features such as shock prevention and short-circuit protection add to their appeal.

Common Applications

Terminal blocks find extensive use in industrial automation for controlling machinery, power distribution systems, and building wiring for electrical fixtures. Their adaptability makes them suitable for various scenarios, contributing to efficient electrical setups.

Selecting the Right Terminal Block

Choosing the appropriate terminal block involves considering factors like voltage and current ratings, wire size compatibility, environmental conditions, and mounting options. Matching the requirements with the types available ensures optimal functionality.

Maintenance and Troubleshooting

Regular maintenance, including inspections and cleaning, prolongs the lifespan of terminal blocks. Understanding and addressing common issues like loose connections or insulation deterioration is crucial for uninterrupted operations.

Future Trends in Terminal Blocks

The evolution of terminal blocks involves technological advancements, including smart terminal blocks with integrated sensors or communication capabilities. Industry innovations aim to enhance efficiency and reliability in electrical systems.

Safety Regulations and Compliance

Adhering to safety standards and certifications is imperative in selecting and installing terminal blocks. Compliance with regulations ensures the safety of installations and reduces potential risks.

Environmental Impact

Manufacturers are increasingly focusing on sustainability efforts in terminal block production. From using eco-friendly materials to offering recycling options, minimizing environmental impact is becoming a priority in the industry.

Case Studies

Real-world examples demonstrate the effectiveness of terminal blocks across diverse applications, showcasing their role in enhancing efficiency and reliability in electrical systems.

Comparison with Alternatives

Terminal blocks offer advantages over traditional wiring methods, such as enhanced organization, easier maintenance, and adaptability to evolving electrical setups.

Tips for Efficient Use

Maximizing the benefits of terminal blocks involves proper installation, regular maintenance, and selecting the right type for specific applications. Efficient use ensures optimal performance and longevity.

Conclusion

Terminal blocks play a pivotal role in simplifying electrical connections across various industries. Their versatility, safety features, and adaptability make them indispensable components in modern electrical systems, ensuring efficient functionality and streamlined wiring processes.