Indicator Lights, commonly referred to as LED Indicator Lights, are a specialized type of signal lights gaining worldwide attention. Two key players in this domain are APEM and FILN, originating from the West and East respectively.

APEM: The Western Pioneer

Originating from France, APEM entered the indicator light market in 2003.

They focus not just on production but also technological innovation, elevating the performance, durability, and design of their LED Indicators.

Over time, APEM has become a leader in this segment globally.

FILN: The Eastern Trailblazer (www.indicatorlight.com)

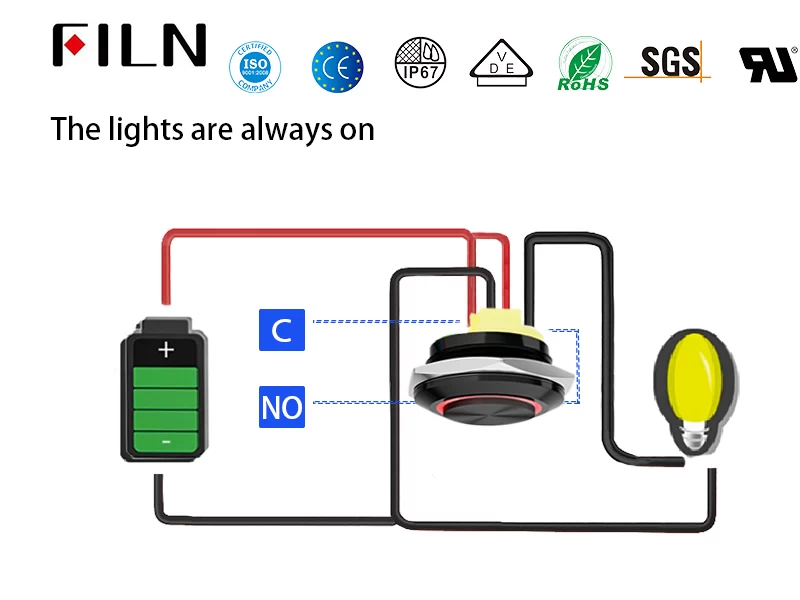

In contrast, FILN started its journey in China as early as 1998. FILN integrates Eastern culture and market needs into their products. Offering both standard and custom lights, FILN’s products are highly functional and versatile, winning the hearts of many consumers.

Both companies have differing technologies and market strategies, but they share the common goal of providing high-quality indicator lights. These lights improve operational safety and provide timely alerts during equipment malfunctions.

The Evolution of Indicator Lights

Indicator lights, these small yet crucial components, hold an irreplaceable role in modern industrial and domestic appliances. The history of these lights reflects mankind’s constant pursuit of technological advancement.

From Neon to LED:

Originally, neon lights were the primary source for indicator lights. As technology advanced, LEDs came into the picture with lower power consumption, longer lifespan, and a broader range of colors, replacing neon as the main source.

Material Advancements:

While early lights were primarily plastic, advancements in technology have made metal the preferred choice due to better heat dissipation, increased durability, and a premium feel.

Waterproofing Technology:

As demands for environmental adaptability grew, waterproof technology also found its way into indicator lights, underlining our ongoing pursuit of safety and reliability.

Distinguishing Between Indicator Light, Signal Light, and Pilot Light:

Understanding the subtle differences between these types of lights can be beneficial for more precise applications.

Definitions and Functions

- Indicator Light: Mainly shows the status of equipment or systems, like power on/off or charging.

- Signal Light: Used for warnings or notifications and is generally brighter than indicator lights.

- Pilot Light: Primarily serves to guide a pathway or position and stays continuously lit to indicate operational or safe conditions.

Application Scenarios

- Indicator Light: Common in household appliances, electronics, and computer hardware.

- Signal Light: Extensively used in industrial machines, traffic signals, and emergency exits.

- Pilot Light: Typically found in large machinery, aiding operators for the next steps or ensuring safe operation.

Color and Shape

- Indicator Light: Comes in various colors and shapes like red, green, or blue depending on requirements.

- Signal Light: Color is generally indicative of the warning it represents, such as red for danger and green for safe.

- Pilot Light: Color and shape can vary based on specific usage but mainly provides clear directional guidance.

In conclusion, although there may be some overlap in appearance and functionality among these lights, each has its unique applications and importance. Understanding these differences is key when choosing and using these lights.