In the world of electronics, the momentary switch stands as a pivotal component, offering both simplicity and versatility in a wide array of applications. Whether you’re a DIY enthusiast, an electronics hobbyist, or someone venturing into this field for the first time, learning how to connect a momentary switch is an essential skill. This guide will walk you through everything you need to know, from understanding the switch itself to safely connecting it in various circuits.

Overview of Momentary Switches and Their Applications

Momentary switches, often referred to as push-to-make or push-to-break switches, are ubiquitous in modern electronics. They are the small but mighty devices behind many everyday interactions, like ringing a doorbell, activating a computer power button, or resetting electronic devices. The primary characteristic of a momentary switch is that it only remains active as long as it’s being pressed. Once released, it returns to its default state, either completing or breaking the circuit depending on its configuration.

These switches are vital in situations where a temporary connection is needed. Because of their design, momentary switches find themselves in various applications—from simple DIY projects to complex industrial systems.

What is a Momentary Switch?

A momentary switch is an electrical switch that only makes or breaks a connection while the actuator (the part that is pressed) is engaged. Unlike a maintained switch, which stays in one state until actuated again, a momentary switch reverts to its original position when released. This type of switch is classified into two main types: Normally Open (NO) and Normally Closed (NC).

Normally Open (NO) Momentary Switches: In this configuration, the circuit is incomplete until the switch is pressed, creating a connection.

Normally Closed (NC) Momentary Switches: In contrast, the circuit remains complete until the switch is pressed, breaking the connection.

Momentary vs. Maintained Switches: What’s the Difference?

Understanding the difference between momentary and maintained switches is crucial when selecting the right switch for your project.

- Momentary Switches: As mentioned, these only activate when pressed and deactivate when released. They are ideal for short-duration tasks such as signaling, activating devices momentarily, or initiating a process that doesn’t need continuous operation.

- Maintained Switches: These switches stay in their new state until they are actuated again. Common in light switches and toggle switches, maintained switches are better suited for applications requiring a persistent change in the circuit state.

The decision between the two depends on your project’s requirements. Momentary switches are preferred in scenarios where short-term control is needed without a continuous current flow.

Common Uses of Momentary Switches

Momentary switches are versatile and can be found in a wide range of applications. Some of the most common uses include:

- Doorbells: When you press a doorbell, the circuit closes and sends power to the bell or chime, which rings until the button is released.

- Reset Buttons: In many electronic devices, a momentary switch is used to reset the device, ensuring that the action only happens when the button is pressed.

- Keyboards: Each key on a keyboard functions as a momentary switch, sending a signal only when pressed.

- Industrial Controls: Momentary switches are often used in machinery controls, where they might be employed to initiate a process or machine operation temporarily.

Types of Momentary Switches

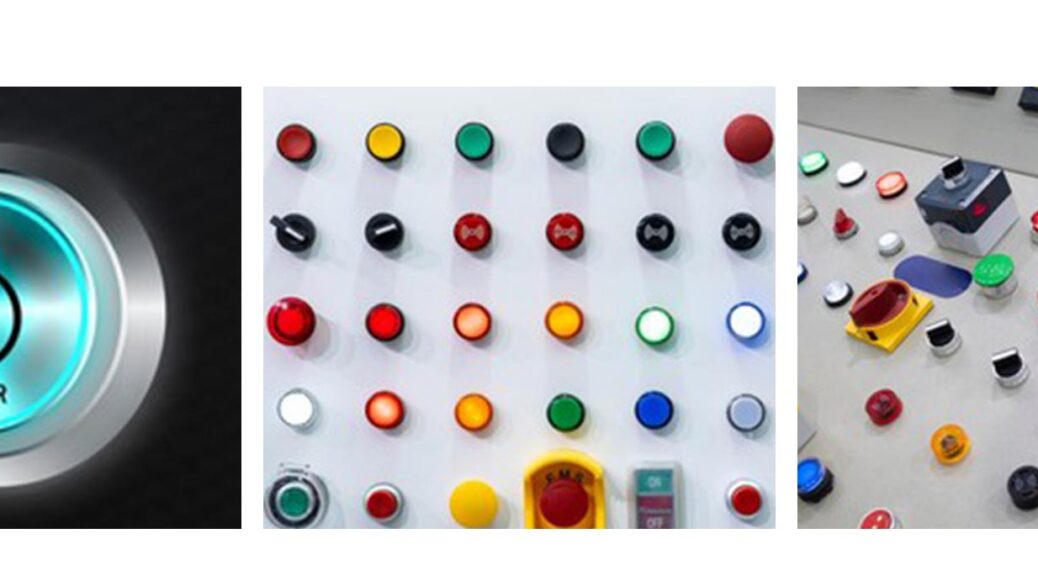

Momentary switches come in various designs and configurations to suit different applications. Some of the common types include:

- Push Button Switches: The most recognizable type, activated by pressing down on a button.

- Toggle Momentary Switches: These appear similar to traditional toggle switches but return to their original position after being actuated.

- Foot Switches: Common in applications where hands-free operation is required, such as in guitar pedals or sewing machines.

- Rotary Momentary Switches: These switches activate when turned but spring back to their default position after being released.

Each type of momentary switch serves specific needs and can be selected based on the requirements of your project.

Essential Tools for Connecting a Momentary Switch

Before you dive into connecting a momentary switch, having the right tools at hand is crucial for a smooth and successful operation. Here’s a list of tools you’ll likely need:

- Screwdrivers: Both flathead and Phillips types, depending on the switch terminals.

- Wire Strippers: For removing the insulation from the ends of your wires.

- Soldering Iron and Solder: If a permanent connection is required, these tools will help you securely attach wires to terminals.

- Multimeter: To test the connections and ensure continuity in the circuit.

- Electrical Tape: For insulating connections and preventing shorts.

- Heat Shrink Tubing: Provides a more durable insulation compared to electrical tape, especially useful in environments with movement or vibration.

Choosing the Right Momentary Switch for Your Project

Selecting the correct momentary switch depends on the specifics of your project. Consider the following factors:

- Current and Voltage Rating: Ensure the switch can handle the electrical load it will control. Using a switch with a lower rating than your circuit could lead to failure or a safety hazard.

- Size and Mounting Style: The physical dimensions and mounting method (e.g., panel mount, surface mount) should fit your project’s design.

- Actuation Force: Different switches require different amounts of pressure to activate. Choose a switch that feels comfortable for the intended use.

- Environmental Factors: If the switch will be used outdoors or in harsh environments, look for a switch with appropriate environmental sealing.

Understanding Basic Electrical Circuits

Before connecting a momentary switch, it’s important to have a basic understanding of how electrical circuits work. At its core, an electrical circuit is a closed loop that allows electricity to flow from a power source, through a load (such as a light bulb or motor), and back to the source.

The flow of electricity is controlled by switches, which either complete (close) or break (open) the circuit. In the case of a momentary switch, the circuit is only closed (or opened) for the duration of the button press.

What is a Normally Open (NO) Circuit?

In a Normally Open (NO) circuit, the default state is “open,” meaning that the circuit is incomplete and no current flows. Pressing the momentary switch temporarily completes the circuit, allowing electricity to flow. This configuration is often used in applications where the switch’s purpose is to momentarily power a device, such as a doorbell or a buzzer.

What is a Normally Closed (NC) Circuit?

Conversely, in a Normally Closed (NC) circuit, the default state is “closed,” meaning the circuit is complete and electricity flows continuously. Pressing the momentary switch breaks the circuit, interrupting the current flow. This setup is useful in safety systems, where the circuit should normally be closed, and the switch is used to break the connection only when necessary.

Power Sources: Batteries vs. Power Supplies

When connecting a momentary switch, you’ll need a power source. The two most common options are batteries and power supplies.

- Batteries: Batteries are portable and provide a DC (direct current) power source. They are ideal for small, mobile projects where AC (alternating current) power isn’t available.

- Power Supplies: Power supplies convert AC from the wall into a stable DC output. These are better for stationary projects that require a continuous power source.

Step-by-Step Guide to Connecting a Momentary Switch

Now that you have a good understanding of momentary switches and the basics of electrical circuits, it’s time to get hands-on with connecting your momentary switch. Follow these steps carefully to ensure a successful connection.

Preparing Your Workspace and Safety Precautions

Before starting any electrical work, it’s essential to prepare your workspace. Ensure that your work area is clean, dry, and well-lit. Avoid working on live circuits; always disconnect power before beginning your work. Wear safety goggles to protect your eyes from any sparks, and if you’re soldering, work in a well-ventilated area to avoid inhaling fumes.

Step 1: Identify the Terminals on the Momentary Switch

Momentary switches typically have two or more terminals. These terminals are where you’ll connect your wires.

- Two-Terminal Switches: If your switch has two terminals, one terminal is for the input (from the power source) and the other for the output (to the load).

- Three-Terminal Switches: Some switches have three terminals, which might include a common terminal (COM) and separate Normally Open (NO) and Normally Closed (NC) terminals.

Identify these terminals before proceeding, as connecting wires to the wrong terminals can prevent the switch from functioning correctly.

Step 2: Connect the Momentary Switch to the Circuit

With your terminals identified, it’s time to connect the switch to the circuit:

- Connect the Power Source: Attach the positive wire from your power source (battery or power supply) to the appropriate terminal on the momentary switch (typically the COM or input terminal).

- Connect the Load: Connect a wire from the NO terminal to the positive side of your load (e.g., a motor or LED).

- Complete the Circuit: Attach the negative wire from your power source to the negative side of your load. This completes the circuit.

If you’re using a Normally Closed configuration, the process is similar, but the load connects to the NC terminal instead.

Step 3: Test the Connection

Once the switch is connected, it’s time to test the circuit:

- Power On: Turn on your power source. If you’re using a battery, ensure it’s charged.

- Press the Switch: Engage the switch. In a Normally Open circuit, the load should activate while the button is pressed. In a Normally Closed circuit, the load should deactivate.

- Check for Issues: If the load doesn’t respond as expected, recheck your connections. A multimeter can help verify that the switch is functioning correctly by checking continuity.

Wiring a Momentary Switch in a Simple Circuit

A simple circuit is a great starting point for anyone new to working with momentary switches. Here’s how to wire a momentary switch to a basic circuit with a power source and an LED:

- Connect the Positive Wire: Attach the positive wire from your power source to one terminal of the momentary switch.

- Connect the Load: Run a wire from the other terminal of the switch to the positive leg (longer leg) of the LED.

- Complete the Circuit: Connect the negative leg of the LED to the negative wire of the power source.

In this setup, the LED will light up when you press the momentary switch, completing the circuit.

How to Wire a Momentary Switch with an LED

Wiring a momentary switch to control an LED is straightforward and a great way to visualize how these switches work:

- Connect the Power Source: Run the positive wire from your power source to one terminal of the switch.

- Connect the LED: Attach a wire from the other terminal of the switch to the positive side of the LED.

- Complete the Circuit: Connect the negative side of the LED back to the power source’s negative terminal.

When you press the switch, the circuit completes, allowing current to flow through the LED, lighting it up.

Tips for Soldering Wires to a Momentary Switch

Soldering provides a secure and durable connection but requires a steady hand and attention to detail. Here are some tips:

- Clean the Surfaces: Ensure the switch terminals and wires are clean before soldering.

- Use the Right Amount of Solder: Too much solder can create bridges between terminals, causing shorts. Use just enough to cover the connection.

- Heat the Connection, Not the Solder: Apply the soldering iron to the terminal and wire first, then touch the solder to the heated area.

Common Issues and How to Fix Them

Even with careful setup, issues can arise when connecting momentary switches. Here’s how to troubleshoot some common problems:

- No Response When Pressing the Switch: Check the power supply and ensure the switch is properly connected. Use a multimeter to test for continuity when the switch is pressed.

- The Load Stays On/Off Regardless of the Switch: This could be due to a short circuit or a miswired switch. Double-check your connections, especially around the switch terminals.

- Switch Doesn’t Spring Back: If the switch doesn’t return to its default position, it might be physically damaged or dirty. Cleaning the switch or replacing it might be necessary.

Momentary Push Button Switch FAQ

- How does a momentary switch differ from a regular switch?

A momentary switch only stays active while being pressed, while a regular (maintained) switch stays in its new state until actuated again. This makes momentary switches ideal for applications requiring temporary control. - Can I use a momentary switch to control a light bulb?

Yes, but the light will only stay on while the switch is pressed. For continuous lighting, a maintained switch is recommended. - What type of wire should I use with a momentary switch?

Use wire that matches the current and voltage requirements of your circuit. For low-power applications, 22-24 gauge wire is typical, while higher currents may require thicker wire. - How can I make my momentary switch more responsive?

Ensure the switch is clean and free of debris. Regularly inspect the internal mechanism, and if necessary, apply a small amount of contact cleaner. - Is it safe to use a momentary switch with high voltage?

Only if the switch is rated for high voltage. Always check the switch’s specifications and ensure it matches the requirements of your circuit to avoid hazards. - What should I do if the switch doesn’t return to its default position?

The switch may be stuck due to dirt or physical damage. Try cleaning the switch or, if the issue persists, replace it to ensure proper functionality.

Summary and Final Thoughts on Connecting a Momentary Switch

Connecting a momentary switch might seem daunting at first, but with the right knowledge and tools, it’s a task that can be accomplished with confidence. Understanding the basics of electrical circuits and the specific role of momentary switches is crucial to ensuring your project works as intended. Whether you’re integrating a switch into a simple LED circuit or a more complex relay system, the steps outlined in this guide provide a solid foundation.

Take the time to choose the right switch, prepare your tools, and follow safety precautions. With practice, you’ll find that connecting a momentary switch is not only straightforward but also a valuable skill in electronics and DIY projects.